We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

Thanks to carbon dating, scientists are reasonably sure that around 43,000 years ago, our ancestors mined Lion Cave for hematite from which to manufacture red ochre.

In Swaziland, Africa, there is the oldest known mine. Thanks to carbon dating, scientists are reasonably sure that around 43,000 years ago, our ancestors mined Lion Cave for hematite from which to manufacture red ochre. Not a significant number of us use red ochre today. However, from those very early attempts at mineral extraction, we now have a world that has become reliant on minerals for the serious business of transport, communication, energy generation, construction and finance, and luxury goods and industrial coatings. While many minerals do not need any special handling, many others do because of abrasiveness and other handling difficulties.

DMN-WESTINGHOUSE manufactures five different rotary valves that are suitable for handling minerals along with two different diverter valves. With so many different minerals used by so many different industries, processing procedures differ significantly. With this in mind, we offer sizes available from 100mm to 500mm for rotary valves and from 50mm to 400mm for the diverters. For recommended rotary valves, a range of different rotor designs is also available to ensure optimum efficiency. For minerals that may have a high wear factor to consider when conveying, special alloys and/or internal coatings can provide additional protection. When it comes to diverter valves, the BTD ball diverter is very suitable for the mineral industry. It has been specifically designed to handle abrasive products such as china clay in pneumatic conveying systems.

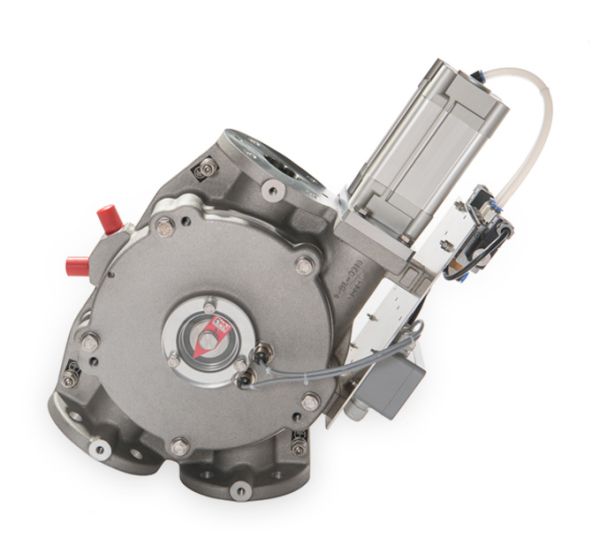

AL/AXLHigh duty rotary valve

AL/AXLHigh duty rotary valve AMLHigh duty rotary valve

AMLHigh duty rotary valve USALHigh duty rotary valve

USALHigh duty rotary valve Blowing seal - BL/BXL/BXXLHigh duty rotary valve

Blowing seal - BL/BXL/BXXLHigh duty rotary valve MLDMedium duty rotary valve

MLDMedium duty rotary valve MALDMedium duty rotary valve

MALDMedium duty rotary valve DLDust filter rotary valve

DLDust filter rotary valve Dual pipe plug diverter - PTD-IIPlug type diverter valve

Dual pipe plug diverter - PTD-IIPlug type diverter valve Single pipe plug diverter - SPTDPlug type diverter valve

Single pipe plug diverter - SPTDPlug type diverter valve Single pipe plug diverter - SPTDSPlug type diverter valve

Single pipe plug diverter - SPTDSPlug type diverter valve Gravity plug diverter - GPDPlug type diverter valve

Gravity plug diverter - GPDPlug type diverter valve Flap Type Diverter - FDVFlap type diverter valve

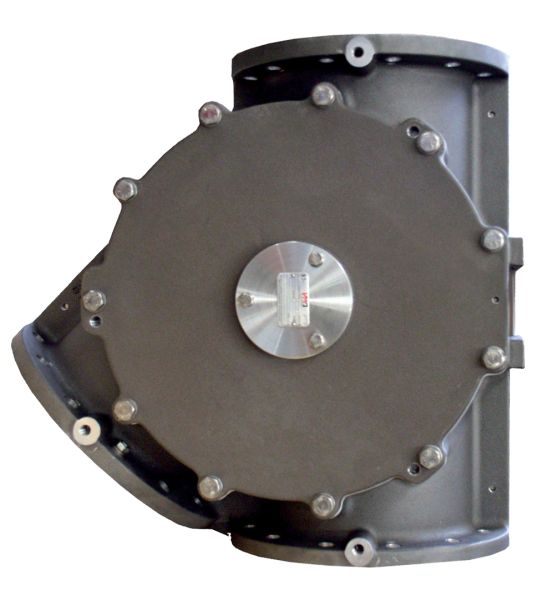

Flap Type Diverter - FDVFlap type diverter valve Ball type diverter - BTDBall type diverter valve

Ball type diverter - BTDBall type diverter valve